|

Well, maybe not so

simple...

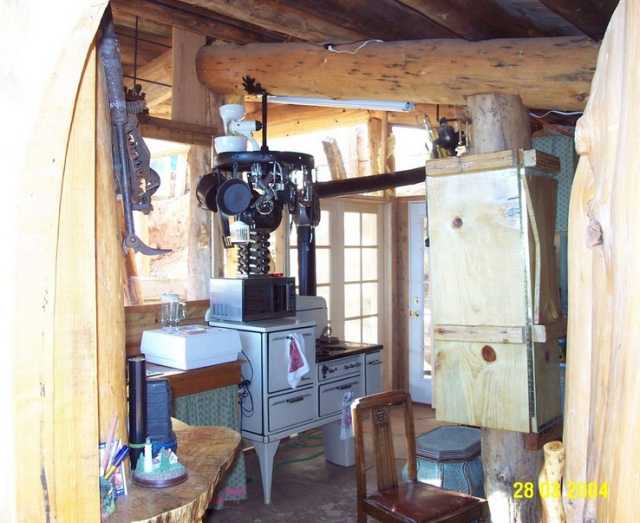

An older interior

shot with

a

bit of a Montana Lodge flavor.

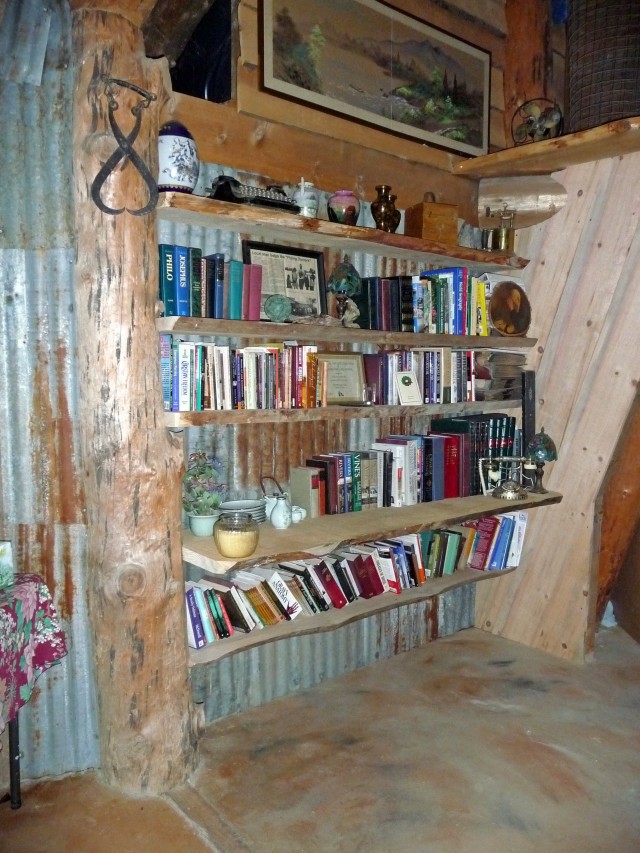

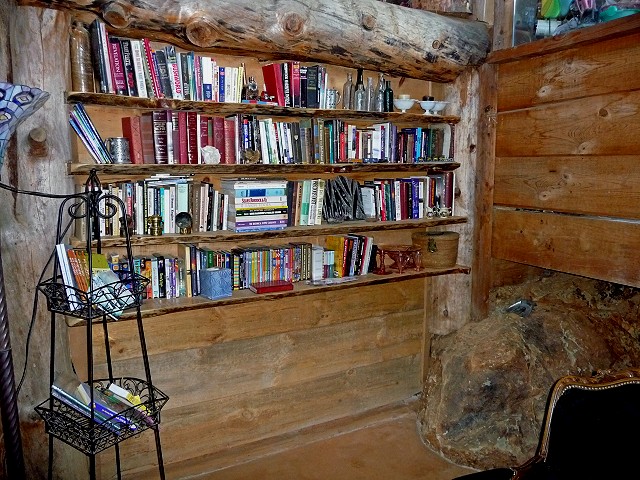

Here's the

big family room where up to 30 people can gather. Ancient iron roofing

panels were reclaimed as a wall finish and room divider. "The walls in

the great room were stick framed with reject 2x4s and then covered with

salvaged plywood from fruit bins. Next the walls were paneled

with corrugated sheeting rescued from a burned out old gold

mine

mill, giving it that ancient 'out of our price range restaurant' look

that custom commercial builders strive for today."

The floor

has its own interesting history. "We have tried many different methods

in experimenting with alternative floor materials. The front

porch area is a cob floor covered with several coats of thinned boiled

linseed oil. It is a more durable floor than the apartment

area interior floors which are soil cement. The cement in the

mix arrests shrinkage making the floor softer and easier to damage. The

soil cement floors must have a new layer of sealer applied every few

months to prevent dusting."

"In the kitchen we partially solved that problem with the torn paper

bag floor sealed and glued with layers of waterbase polyurethane.

However the soft substrate still allows damage to it in places too."

"We

have finally settled on the CBRI light duty concrete floor designed in

India and brought to our attention in Ken Kern's book, 'The Owner Built

Home'. This appears to be the most cost effective and durable

floor of all. It is used throughout the great room (above)

and

the lower level of the house. Later we plan to refinish the

upstairs floors with the CBRI floor system."

"Variations of it that I have designed can be used over nearly any

surface. Only 1/8 the thickness of most house floor slabs,

this floor is colorful, environmentally friendly and as

durable as a full thickness slab without the wasted

concrete. Tractors need a 4" concrete slab... humans do not."

"Plunger

support piers are made in the soft ground every 2 to 3 feet with a

tamping bar to get down to undisturbed soil. These holes are

filled with grout and a 1/4" layer of a cement rich stucco is applied

to jute reinforcement laid on top. This is followed the next day with

another 1/4" final coat reinforced with fibermesh. Colors, as desired,

are lightly troweled into the surface and then hard troweled for a

smooth variegated finish. It is not necessary or desirable to

compact the soil under this type of floor - the piers bridge the spaces

and over time the loose soil settles creating an insulating air

gap. Rated at 50 psf it is plenty strong, but in reality it

has

been tested at up to 250 psf and we have had no failures."

This gives a feel for

the kitchen and the old cook stove area.

"A high end

Magic Chef RV cooktop fit perfectly into the kitchen island and greatly

improved our ability to rapidly burn a meal if necessary. The

old (1935) C Wedgewood is now used mostly for baking but it is still

working...just quite a bit slower."

Glenn and Kathy

cooking on the new stovetop.

These

two photos are an example of the plunger pile composit concrete floor

(with color added). For more information on this inexpensive floor

system click HERE.

"Books give

the impression of being scholarly even if I sometimes get too bored to

read the whole book. The worn and studied books belong to

Sassy (Kathy). So, to get people to take me seriously... I

build lots of book shelves."

A group photo of

visitors who made a special request to see the Mountain Man's cabin

before his parents went back to China.

"A wild

grape vine serves as a handrail for the spiral stairway up to kitchen

level on the bridge. Grown to fit the curve of the stair by

mother nature, all it required was a bit of shopping near an old gold

mine and me going... 'Hey, I know where I can use that... '

Some day I will get the room under the bridge

going too...as soon as I am ready for some jackhammer work."

"The guest

loft above the pantry was added this year as were a lot of the other

improvements. It's just that sometimes it takes nine years to

decide what you're really going to do with otherwise useless space. In

such a house as this things just evolve, without the need for

predefined plans and code approved documents."

"Here is a

shot of a new section of the solar array going in. This set takes the

off-grid complex up to around 5000 watts of production from the panels.

The wind generator is still putting out pretty much daily and even more

during storms. We also have a 500 amp/10,000 watt

welder/generator as backup for extended storms. I actually

use the welder set on 220 amps DC for most of the charging along with

the inverter charger to boost the batteries in time increments of about

1/2 hour during storms. We are still using some of the

batteries we installed in 2004. We generally have enough

excess power production in the daytime to run everything without

drawing down much on the batteries."

|

You can follow all the progress and

banter of this

and other projects of Glenn's at his Forum

Pages. Be

advised, this thread has over 104 pages of

ongoing forum discussion! (Glenn has explained just about everything he

has built over the years.)

For

a fun video tour of this house from Major Miracles

(aka Mike Oehler) click below.

|

|

For an

email message to Glenn click HERE

|